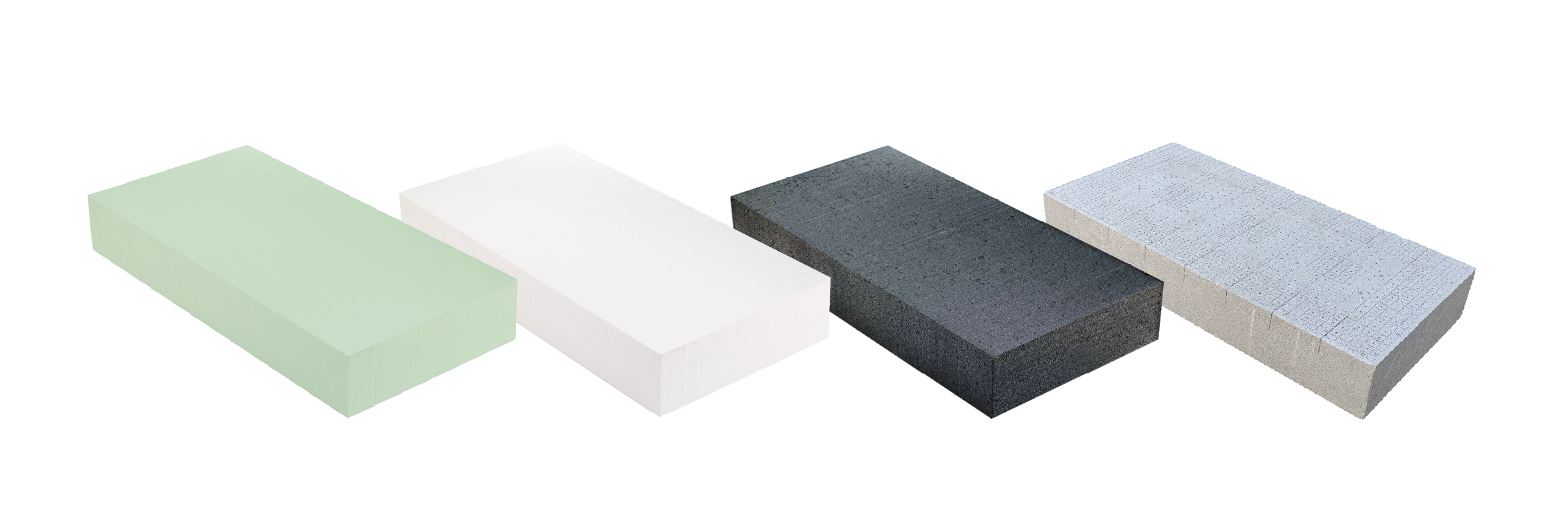

EPS (expanded polystyrene), more commonly known as styrofoam, has excellent mechanical properties, it is an excellent thermal and sound insulator, and has the best ratio between price and thermal insulation of all insulations on the market. They differ according to the purpose of use, according to thermal conductivity, compressive strength, cell structure.

All thermal insulation materials must have the appropriate certificate that they are suitable for installation in the facade system. SIST EN 13163:2013+A1:2015

Why is EPS (styrofoam) most often used for insulation?

- Excellent thermal and sound insulator.

- Low water absorption.

- Stable and durable – properties do not change with aging.

- Vapor permeable.

- It does not irritate and does not crumble.

- It has good mechanical properties with low weight.

- Environmentally friendly – easy to recycle.

- Excellent adhesion with adhesives and mortars.

- Dimensionally stable.

- Simple processing during installation (cutting, grinding).

- Resistant to water and humidity (submergence, flooding).

- Prevents the retention of humidity in the facade system.

- Self-extinguishing and inert – as part of the JUBIZOL facade system classified in fire class B-d1.

Did you know?

- 98 % of styrofoam consists of air and only 2 % of polystyrene.

- Styrofoam is a very durable material, it has been installed for decades and tests in real conditions have proven that its physical properties do not change over time.

- In Europe, more than 80 % of facade systems are based on thermal insulation from styrofoam.

- Styrofoam does not contain and does not release substances dangerous to ozone during production.

- Styrofoam can be 100 % recycled, over 120,000 tons of EPS are recycled annually in the world.

- The vapor permeability of styrofoam is greater than the vapor permeability of wood and it is optimal in terms of preventing the formation of condensation within the facade system.

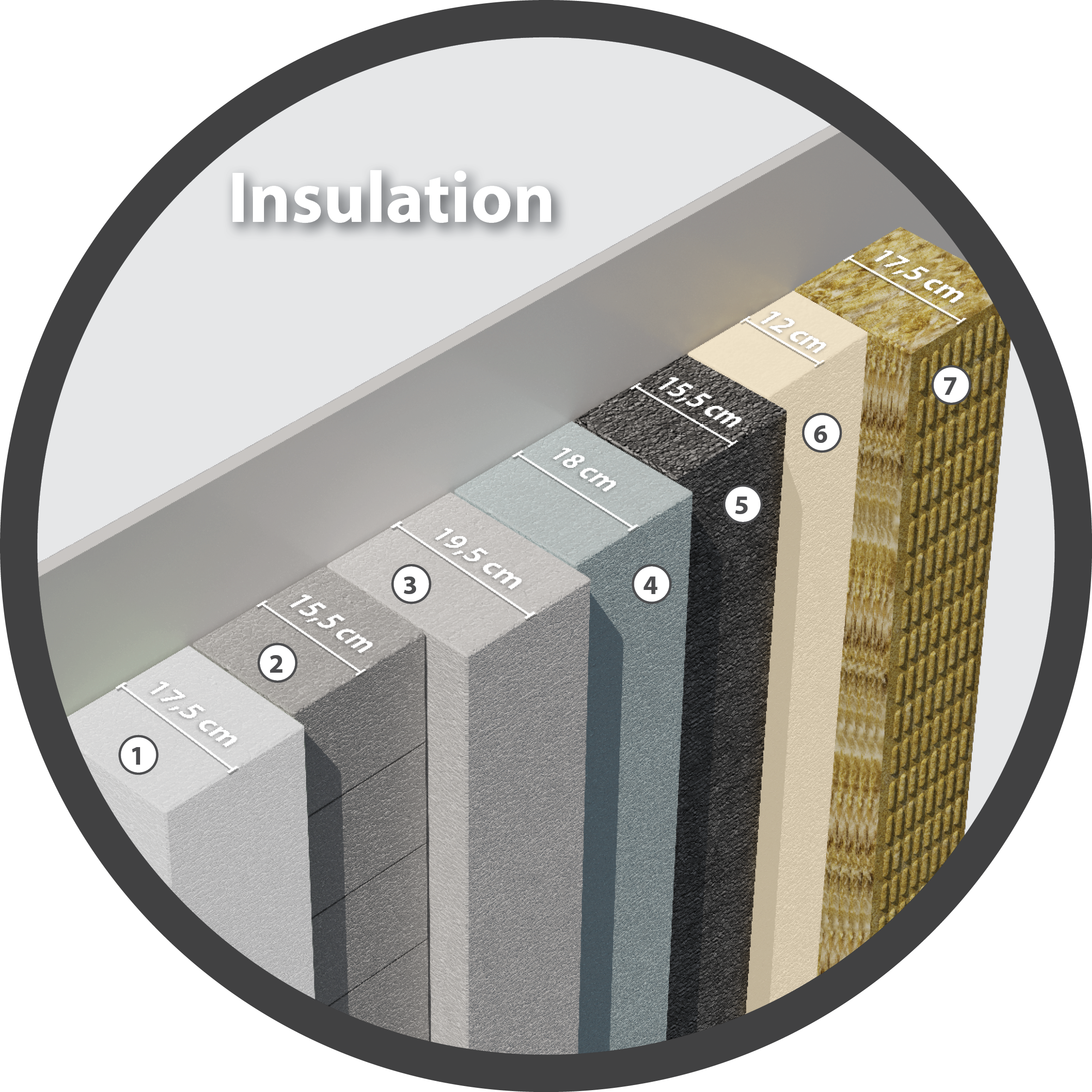

Same effect – different thicknesses

We have a variety of insulating linings available, but they all serve the basic purpose of providing adequate insulation. The table below shows the properties of our insulating linings.

| 1. | 2. | 3. | 4. | 5. | 6. | |

| JUBIZOL | EPS F 035-W0 | JUBIZOL EPS F Effect Plus | EPS F-W0 | EPS F Strong premium | EPS F-G0 | Mineral wool boards |

| Description | EPS with improved strength | Silver EPS with improved +20 % insulation and exceptional dimensional stability (panel made in a mould) | White facade EPS | EPS for plinths and buried parts of buildings | Graphite EPS with improved +20 % insulation | MW board for contact facades |

| Thermal conductivity coefficient – lambda [W/mK] | 0,035 | 0,031 | 0,039 | 0,036 | 0,031 | 0,035 |

| Tensile strength [kPa] | 150 | 150 | 150 | 150 | 150 | 150 |

| Pressure strength | 80 | 80 | 70 | 100 | 80 | 30 |

| EKO fund (thickness) [cm] | 17,5 | 15,5 | 19,5 | 18 | 15,5 | 17,5 |